El laminador de alta velocidad que utiliza Votti

Compared with Xuyi Titan’s time, Votti adopted many high speed rolling mills to produce titanium tube. The high speed rolling mill for titanium tube has the characteristics of large diameter reduction, large wall reduction and long working stroke. Meanwhile, it adopts AC servo motor to control rotation and feeding, and uses mandrel chuck and tube blank chuck to work alternately, so as to realize continuous feeding, feeding and rolling without stopping. High output, good precision, reliable and stable work are helping us to meet more requirement from clients.

We take one of the models LG30 as an example to explain how it works:

LG30 cold rolling mill is a two roll cold rolling mill equipment. The main working principle is as follows: start the main motor, large pulley to be driven to rotate by V-belt through the small pulley, through the gear frame, and on the one hand, drive the crank and connecting rod mechanism of the main frame to rotate, so that the main frame makes a linear reciprocating motion, on the other hand, drive the encoder through the gear to transmit the signal to the photoelectric rotary feeding box, so as to ensure the consistent coordination of the main frame motion and rotary feeding motion .

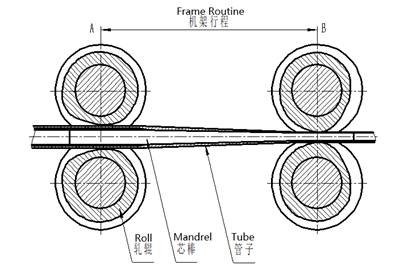

The roller of this rolling mill adopts ring pass, which is characterized by long working stroke and compact structure. The cone pass on the roller and the cone on the mandrel are consistent. In the positive stroke of the reciprocating motion of the main frame, the cone pass is gradually reduced from large to small, so that the tube billet between the cone pass and the cone mandrel is continuously rolled and finished. In the reverse stroke, the cone hole is gradually reduced When a reciprocating stroke is about to end, the tube blank is sent to a certain distance by the mechanical rotary feeding mechanism and rotated to a certain angle, so as to carry out the next reciprocating rolling. The rolling of tube blank into a certain size of tube is the whole process of the two roll cold rolling mill. Following Figure is the schematic diagram of the working principle of LG30 cold rolling mill. When the roll moves from point a to point B (positive stroke rolling), the taper section of pass gradually decreases, and metal deformation such as reducing diameter, reducing wall and finishing occurs between the cone pass and the cone mandrel. When the roll returns from point B to point A (reverse stroke rolling), the taper section of pass gradually increases, and the tube billet continues to be rolled When the conical section is larger than the tube blank section, the mandrel and tube blank are driven to rotate an angle by the rotary feed mechanism at the end of the rolling mill, and the tube blank is sent a certain distance to the metal deformation area in the stand, and then the next reciprocating rolling is carried out. This is how it works.